We have been in the business of providing high-pressure industrial cleaning and unplugging services via waterjetting – technology that uses water jetted at very high pressures, up to 2500 bar.

For comparison, the pressure of water running from the tap at home is in the range of about 4 bar.

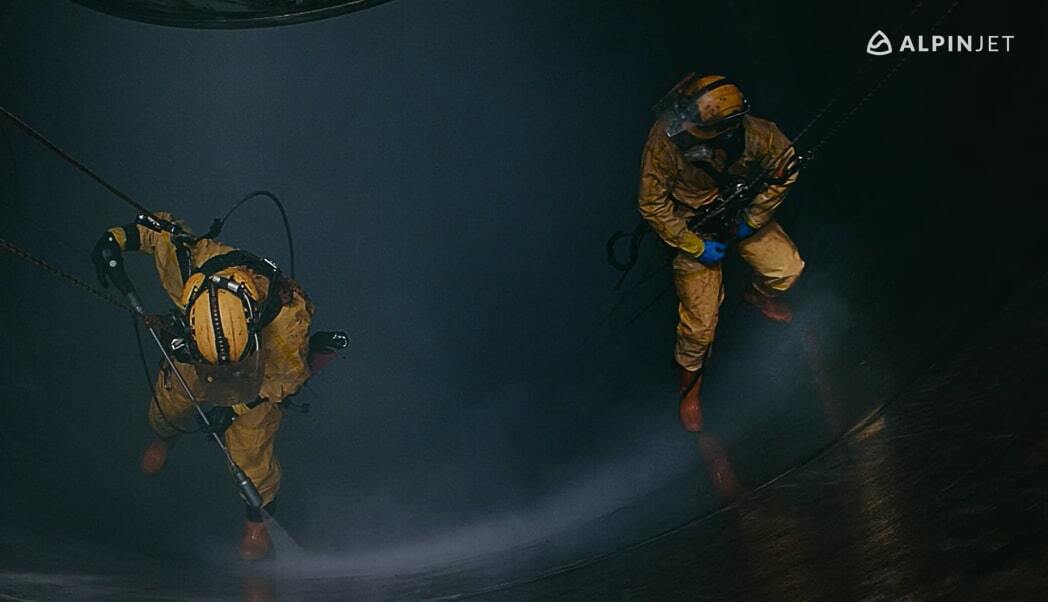

We mainly use waterjetting technology together with rope access methods to conduct cleaning projects. Rope rigging allows our operators to access industrial utilities that would otherwise be inaccessible via other, more traditional means (scaffolding or crane lifts). We can easily work at heights and in confined spaces, which is especially important as the designs of industrial installations and systems are becoming increasingly more complex in facilities worldwide. Our operators are used to working in dark, damp and confined spaces, thus we can take on cleaning tasks in the most demanding, hard-to-access places.

Over the years, we’ve successfully completed cleaning projects for many sectors of the industry – from wood production, chemical processing, food & beverage, pulp & paper to petrochemical and power production. Highly efficient removal of fouling and deposits that accumulate along industrial and technological lines is becoming an urgent need worldwide. We know how crucial time is for every sector of the industry, that’s why in emergency situations, such as during unplanned shutdowns, we respond quickly and act promptly. Our extensive experience and portfolio of successful cleaning projects guarantee expert service and maximum commitment. Our company’s most important attribute are our full-time operators who work together as a team, and we strictly adhere to all safety procedures when planning and conducting any cleaning project.

making it impossible

implementation of the service

Innovative equipment

We use mainly our own equipment for cleaning tasks. We purchase brand-new power units directly from their manufacturers. This guarantees that our cleaning equipment is in perfect working condition and minimizes the need for maintenance or replacement of tools during a cleaning task.

We also invest in state-of-the-art solutions – our most powerful unit was custom made, EU funded and certified as innovative on a global scale. Our company was also the first in Poland to purchase reusable waterjet heads to clean large pipelines and heat exchangers.

We do not limit ourselves to choosing cleaning tools and solutions from one manufacturer, as we can custom design, assemble and implement our own applications that are otherwise unavailable to competitive cleaning service providers.